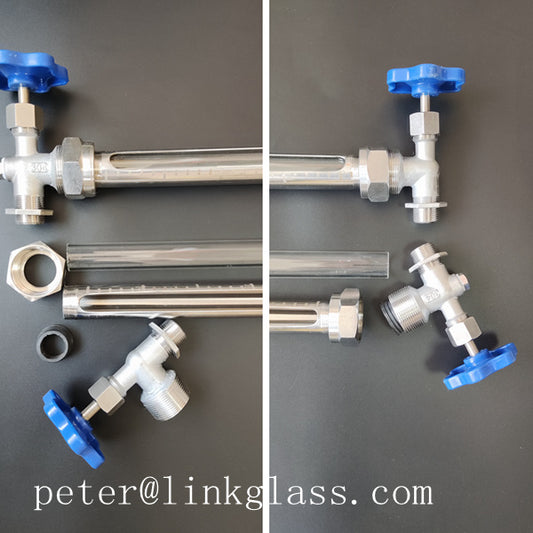

Collection: Cock liquid level gauge/glass tube liquid level gauge

A glass tube liquid level gauge is a type of level measurement device used to monitor the level of liquid in a vessel or tank. It typically consists of a transparent borosilicate glass tube mounted vertically on the side of the vessel. Here's how it works and some key features:

-

Construction: The glass tube is typically connected to the vessel through a valve at the bottom and another at the top. The valve at the bottom allows the liquid to enter the glass tube, while the valve at the top prevents the liquid from overflowing.

-

Transparent Tube: The borosilicate glass tube is transparent, allowing operators to visually observe the level of the liquid inside the tube. Graduations or markings on the tube help provide accurate readings of the liquid level.

-

Valves: The valves at the bottom and top of the glass tube are typically ball valves or needle valves that can be opened or closed manually. Opening the bottom valve allows the liquid to enter the tube, while opening the top valve allows the liquid to drain back into the vessel.

-

Principle of Operation: The liquid level inside the glass tube corresponds to the liquid level in the vessel. When the bottom valve is opened, the liquid enters the tube, rising to the same level as in the vessel. The height of the liquid column in the tube indicates the liquid level in the vessel.

-

Mounting: Glass tube liquid level gauges can be mounted directly on the vessel using threaded connections or flanges. They can also be mounted remotely from the vessel using tubing or piping to connect the glass tube to the vessel.

-

Applications: Glass tube liquid level gauges are commonly used in industries such as chemical processing, oil and gas, power generation, water treatment, and pharmaceuticals. They provide a simple and reliable means of visually monitoring liquid levels in various types of vessels and tanks.

-

Safety Considerations: In some applications, such as those involving hazardous or corrosive liquids, protective shields or coatings may be added to the glass tube to prevent breakage or damage.

Overall, glass tube liquid level gauges offer a straightforward and cost-effective solution for monitoring liquid levels in industrial processes where visual observation is sufficient. They are widely used due to their simplicity, reliability, and compatibility with a wide range of liquids and operating conditions.

-

Stainless steel Cock valve glass tube liquid level gauge

Regular price $0.00 USDRegular priceUnit price / per