LinkGlass

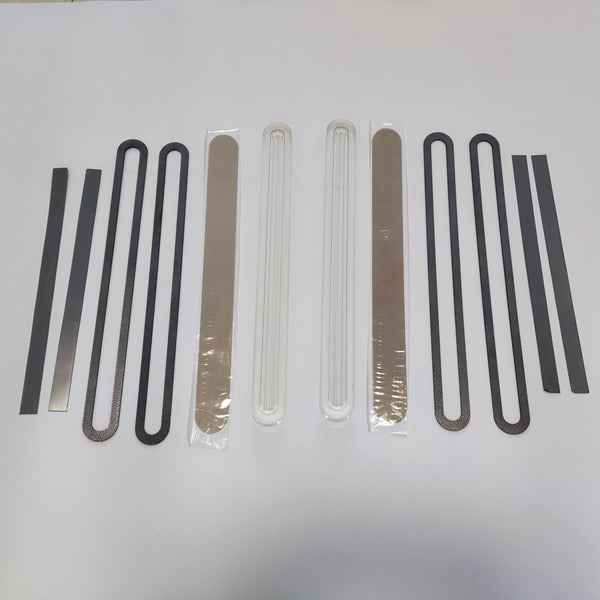

Aluminosilicate glass for liquid level gauge high pressure resistance

Aluminosilicate glass for liquid level gauge high pressure resistance

Couldn't load pickup availability

Aluminosilicate Glass: The Superior Choice for Liquid Level Gauges

Aluminosilicate glass for liquid level gauge high pressure resistance offers unmatched durability and precision in measuring liquid levels in various industrial applications. This specialized type of glass is known for its exceptional thermal and chemical resistance, making it an optimal choice for environments where traditional glass may fail. Aluminosilicate glass combines the properties of alumina and silica, resulting in a material that can withstand high pressure and temperature extremes without compromising performance.

With the continuous advancements in industry standards, the requirement for high-performance materials has never been greater. Aluminosilicate glass stands out as a reliable solution for industries that rely on accurate liquid measurement in pressurized systems. Its robustness allows it to handle harsh conditions while providing clear visibility of the liquid content within gauges.

In addition to its outstanding physical properties, Aluminosilicate glass is also lightweight and easier to handle compared to alternative materials. This characteristic simplifies installation processes and reduces the overall weight of equipment. Moreover, the clarity of Aluminosilicate glass ensures that any fluctuations in liquid levels are easily observed, promoting safety and efficiency in monitoring operations.

One of the critical applications of Aluminosilicate glass is in the manufacture of liquid level gauges used in chemical processing, power generation, and oil and gas industries. These gauges are essential for monitoring liquid levels in tanks, reactors, and pipelines, where precision and reliability are paramount. The excellent bonding characteristics of Aluminosilicate glass with other materials, such as metals and polymers, further enhance its adaptability across various applications.

Aluminosilicate glass also exhibits superior resistance to thermal shock, making it ideal for environments where sudden temperature changes can occur. This property allows it to maintain structural integrity even when exposed to extreme heat or cold, ensuring longevity and reliability in high-demand applications. Furthermore, it is resistant to chemical attack, which is a crucial factor in environments where aggressive fluids are present.

Environmental considerations are also vital when selecting materials for industrial applications. Aluminosilicate glass is a sustainable option, as it can be recycled, thereby reducing waste and promoting eco-friendliness. Its long lifespan and resistance to degradation contribute to minimizing the environmental impact associated with frequent replacements of less durable materials.

To summarize, Aluminosilicate glass is an exemplary material for liquid level gauges used in high-pressure environments. Its exceptional thermal and chemical resistance, combined with its lightweight nature and clarity, makes it the go-to choice for a variety of industrial applications. By investing in Aluminosilicate glass for your liquid level gauge needs, you're ensuring a reliable, efficient, and sustainable solution for your operations.

Share