LinkGlass

PTFE gasket O ring

PTFE gasket O ring

Couldn't load pickup availability

PTFE Gasket O Ring: The Ultimate Sealing Solution

PTFE gasket O ring is a crucial component in many industrial applications, offering exceptional sealing capabilities in various environments. Composed of polytetrafluoroethylene (PTFE), these gaskets exhibit outstanding resistance to chemicals, temperature extremes, and wear, making them ideal for use in harsh conditions. PTFE gasket O rings ensure that sensitive systems remain leak-free, enhancing efficiency and safety in operations.

PTFE (polytetrafluoroethylene) is known for its non-stick properties, high-temperature tolerance, and chemical resistance. This makes PTFE gasket O rings suitable for a wide range of applications, including but not limited to, pneumatic and hydraulic systems, food processing, pharmaceuticals, and chemical manufacturing. The use of PTFE in gasket production ensures that these O rings can withstand aggressive chemicals without degradation.

In addition to their robustness against chemicals and temperature fluctuations, PTFE gasket O rings possess excellent mechanical properties. They maintain their shape and structural integrity even when subjected to significant stress and movement within machinery. This feature is particularly beneficial in applications where dynamic sealing is required.

Installation of PTFE gasket O rings is straightforward, often requiring just the right size for the intended application. Proper installation is critical to ensure that these gaskets perform effectively. Users should ensure that the grooves where the O rings sit are clean, devoid of burrs or contaminants that may impair sealing performance.

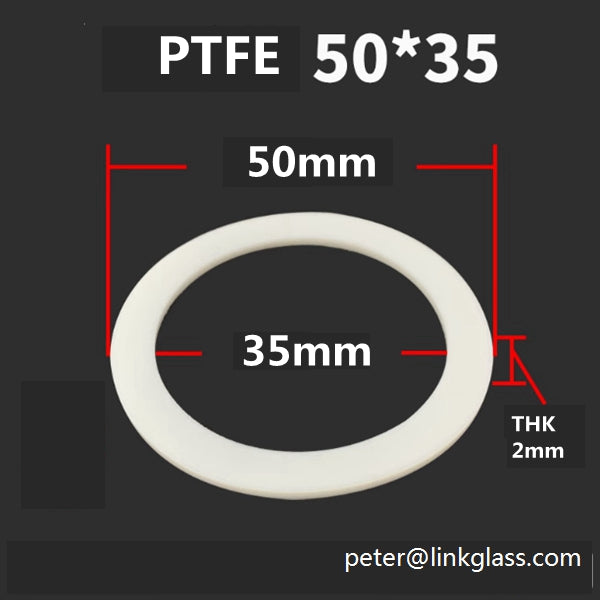

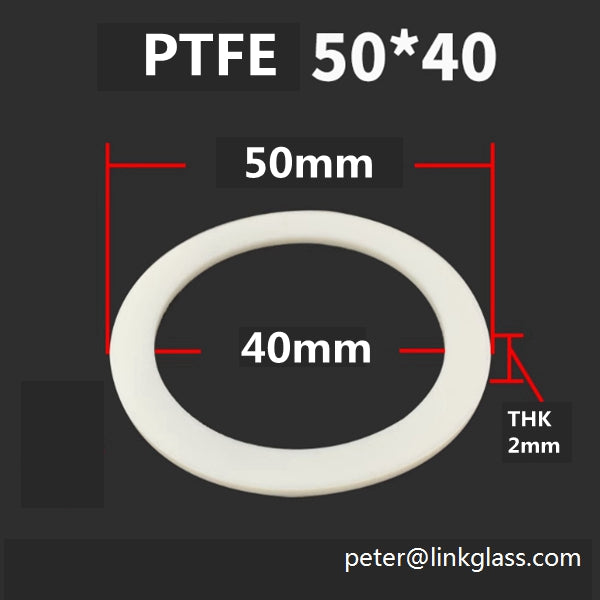

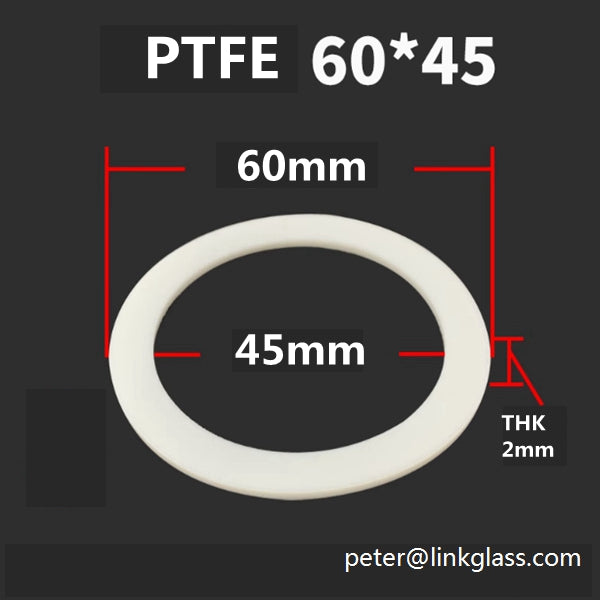

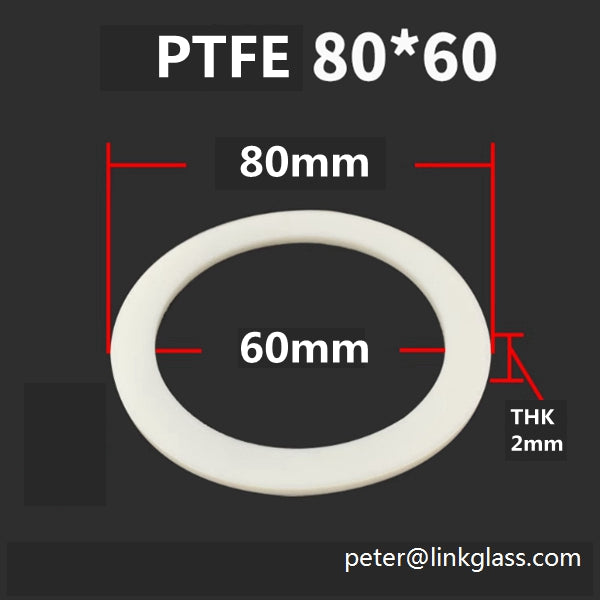

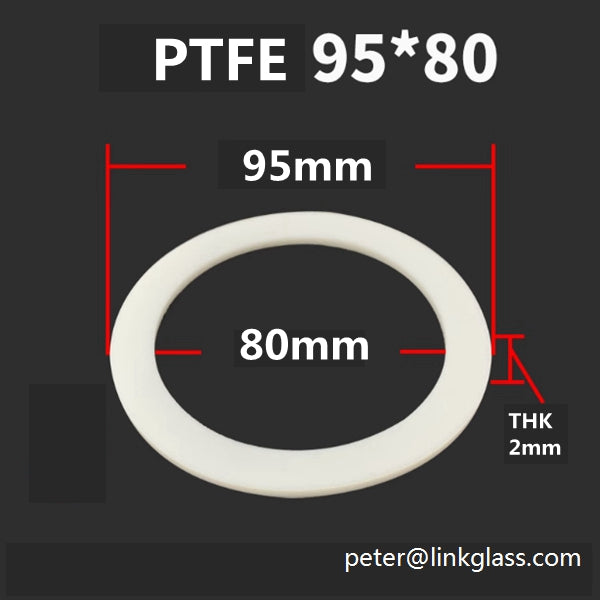

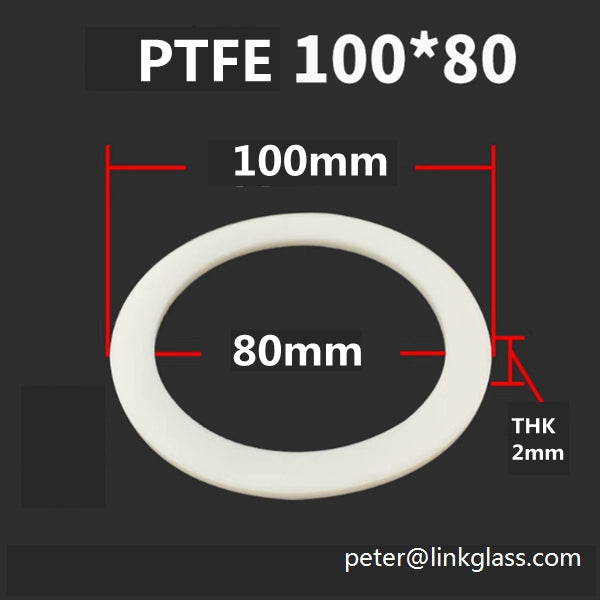

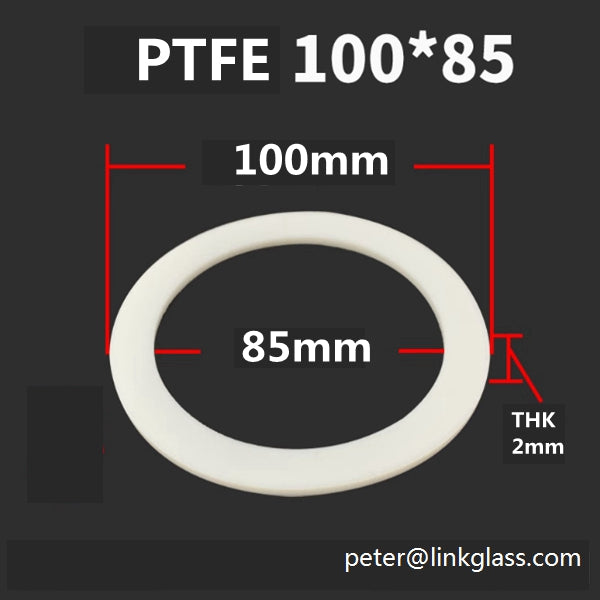

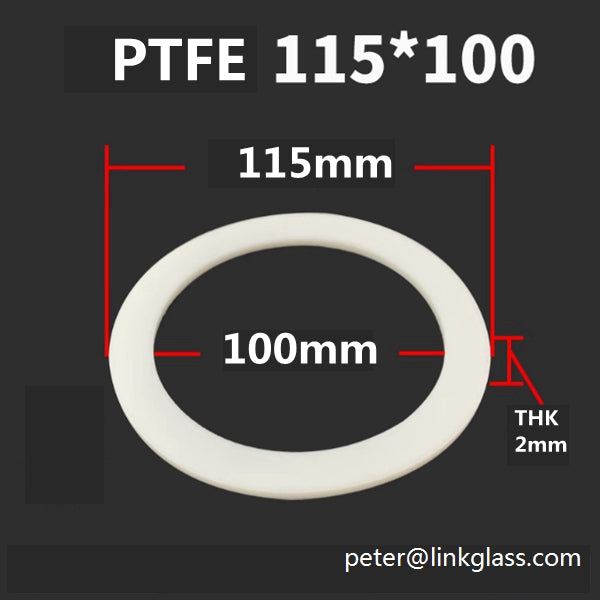

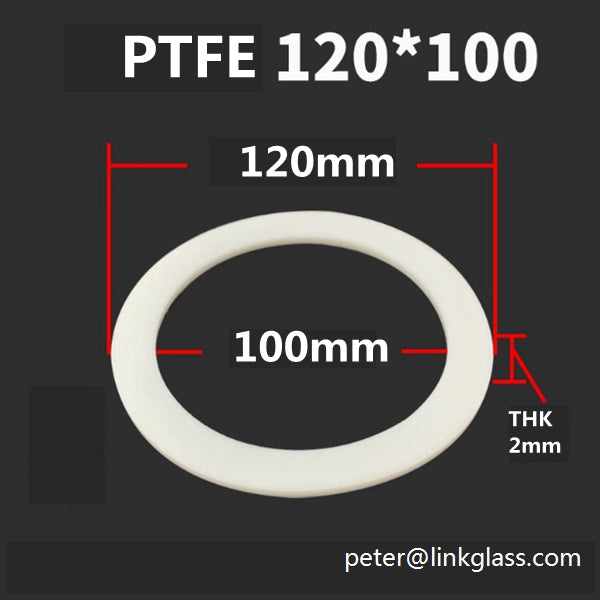

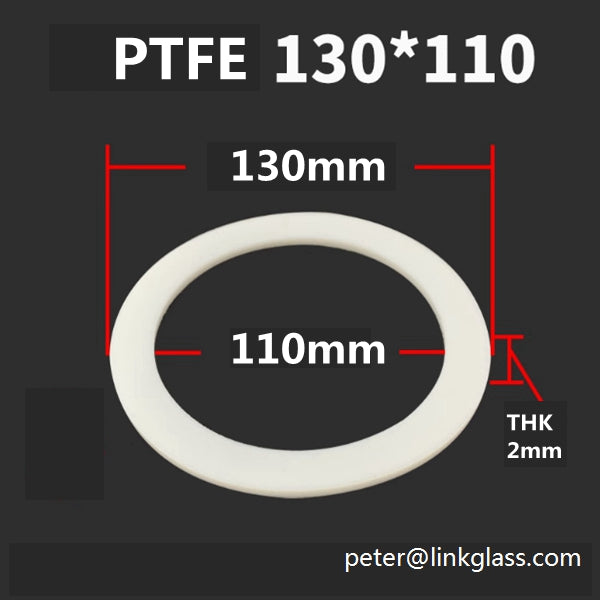

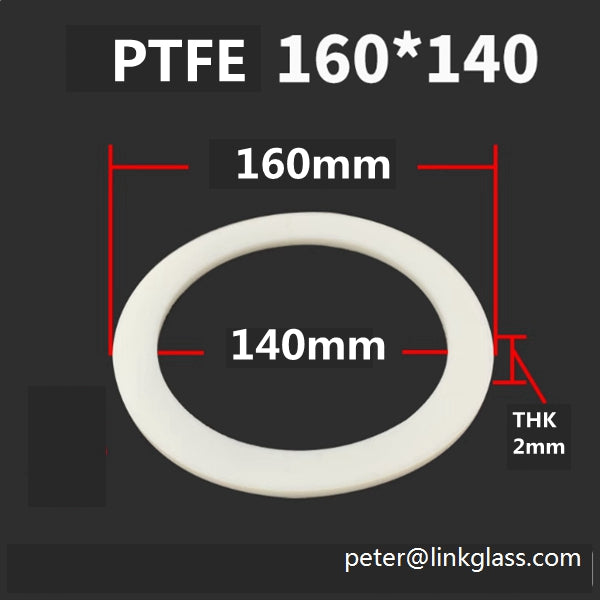

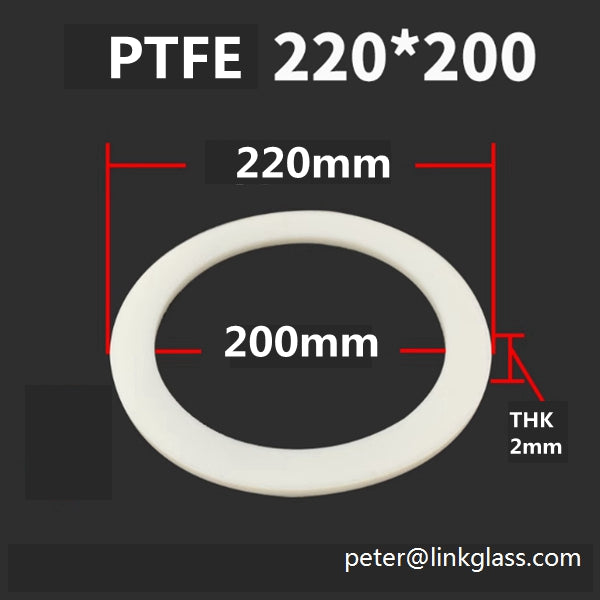

When selecting a PTFE gasket O ring, it is essential to consider the specific requirements of your application. Factors such as temperature, pressure, chemical exposure, and the type of fluid being sealed all play a significant role in choosing the right gasket. PTFE gasket O rings come in various sizes and shapes, allowing for a tailored fit to virtually any machinery or system design.

Applications of PTFE gasket O rings can be seen in numerous industries. In the food industry, for example, these gaskets ensure that products remain uncontaminated while maintaining stringent hygiene standards. In the chemical sector, their resistance to aggressive substances makes them a preferred choice for sealing joints in pipelines and valves.

The durability of PTFE gasket O rings means that they often outlast traditional rubber gaskets, reducing maintenance and replacement costs over time. This longevity reflects not only on cost efficiency but also environmental impact, as fewer replacements mean less waste.

Another critical aspect of PTFE gasket O rings is their versatility. They can be used in both static and dynamic applications, adapting to the needs of various systems. For rotating equipment, specifically designed PTFE O rings can accommodate movement without compromising their sealing abilities.

Manufacturers of PTFE gasket O rings often provide data sheets and technical specifications to aid in selection. These documents typically include details on mechanical properties, maximum operating temperatures, and chemical compatibility charts. Understanding these parameters helps engineers and purchasing managers make informed decisions.

For those in need of custom solutions, many suppliers offer the option to manufacture PTFE gasket O rings to specific dimensions. This custom approach allows for the alignment of O ring profiles to unique industry requirements, which can be crucial for achieving optimal performance.

In summary, PTFE gasket O rings stand out as a vital component for numerous industries due to their remarkable properties and versatility. Whether you are working in aerospace, automotive, food manufacturing, or chemical processing, these gaskets deliver reliable sealing performance that can save time and costs while ensuring operational safety. Choose PTFE gasket O rings for your sealing needs and experience the benefits of enhanced performance.

Share