Collection: Level gauge glass

Level gauge glass, also known as sight glass or gauge glass, is a type of borosilicate glass specifically designed for use in liquid level measurement systems. It is commonly found in industries such as:

-

Chemical Processing: Level gauge glasses are used in chemical processing plants to monitor the levels of various liquids in tanks, reactors, and pipelines. They provide a direct visual indication of the liquid level, allowing operators to monitor processes safely and efficiently.

-

Oil and Gas: In the oil and gas industry, level gauge glasses are employed in storage tanks, separators, and other equipment to monitor the levels of crude oil, refined products, and various chemicals. They play a crucial role in ensuring the safe and efficient operation of production facilities.

-

Power Generation: Level gauge glasses are used in power plants to monitor water levels in boilers, steam drums, and condensers. Maintaining proper water levels is essential for the safe and efficient operation of steam-based power generation systems.

-

Food and Beverage: Level gauge glasses are utilized in food and beverage processing plants to monitor the levels of liquids such as milk, juice, and beer in storage tanks and processing equipment. They help ensure consistent product quality and prevent overflows or shortages.

-

Pharmaceuticals: Level gauge glasses are employed in pharmaceutical manufacturing facilities to monitor the levels of various liquids and solutions used in drug production processes. Accurate level measurement is critical to maintaining batch consistency and product quality.

-

Petrochemicals: Level gauge glasses find application in petrochemical plants for monitoring the levels of chemicals, solvents, and other liquids in storage tanks and processing equipment. They help prevent spills, leaks, and other safety hazards.

-

Water Treatment: Level gauge glasses are used in water treatment plants to monitor the levels of chemicals, sludge, and other liquids in tanks and treatment processes. They aid in maintaining optimal process conditions and ensuring regulatory compliance.

Overall, level gauge glasses are essential components in industries where accurate and reliable liquid level measurement is required for safe and efficient operations. They provide operators with a visual indication of liquid levels, helping to prevent accidents, optimize processes, and maintain product quality.

-

Gasket for level gauge glass

Regular price From $2.00 USDRegular priceUnit price / per -

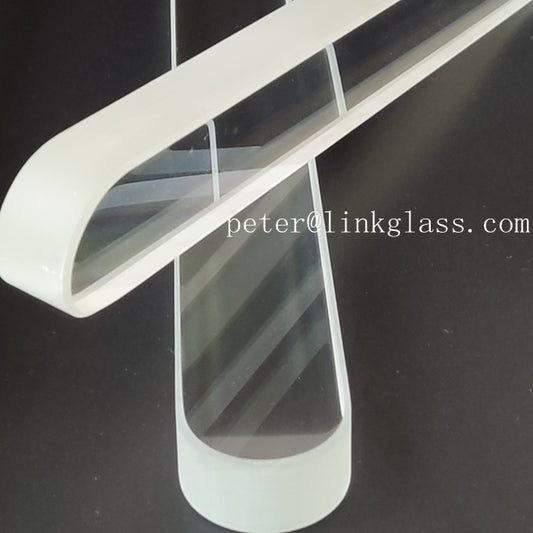

Aluminosilicate level gauge glass

Regular price From $68.50 USDRegular priceUnit price / per -

Transparent level gauge glass

Regular price From $12.50 USDRegular priceUnit price / per -

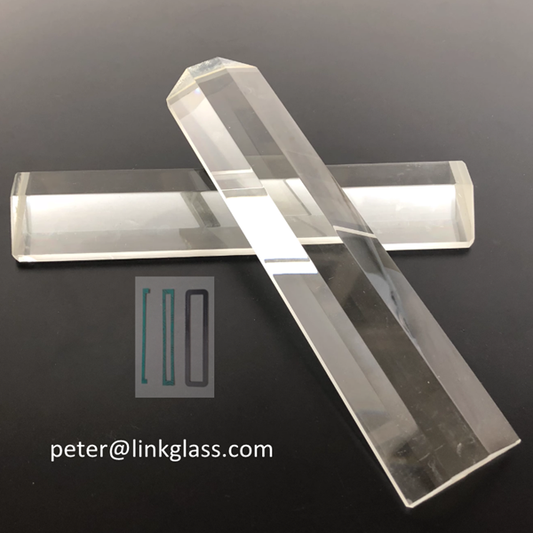

Reflex level gauge glass

Regular price From $13.00 USDRegular priceUnit price / per -

Reflex level gauge glass

Regular price $0.00 USDRegular priceUnit price / per -

level gauge glass

Regular price $0.00 USDRegular priceUnit price / per -

level gauge glass double-color water level gauge glass prism 216*50*22mm trapezoidal glass plate liquid level gauge high temperature resistant glass

Regular price From $18.40 USDRegular priceUnit price / per -

Transparent level gauge glass

Regular price $0.00 USDRegular priceUnit price / per