Collection: Liquid level gauge

A liquid level gauge is a device used to measure and monitor the level of liquid in a container, tank, or vessel. These gauges are essential in various industries for maintaining optimal levels, preventing overflows or shortages, and ensuring the safe and efficient operation of processes. Here are some key points about liquid level gauges:

-

Types: Liquid level gauges come in various types, each suited for different applications and operating conditions. Common types include:

- Float-type gauges: These use a buoyant float that moves up and down with the liquid level, transmitting the level to an external indicator.

- Sight glass gauges: These consist of a transparent tube or pane mounted on the side of the tank, allowing direct visual observation of the liquid level.

- Differential pressure gauges: These measure the pressure difference between the bottom and top of the tank, which corresponds to the liquid level.

- Ultrasonic level sensors: These use ultrasonic waves to measure the distance between the sensor and the liquid surface, providing a non-contact level measurement.

- Radar level sensors: These use radar waves to measure the distance to the liquid surface, suitable for measuring levels in tanks with vapors, foam, or agitated liquids.

-

Principle of Operation: The operating principle varies depending on the type of liquid level gauge. However, most gauges work by detecting changes in buoyancy, pressure, or distance caused by variations in liquid level.

-

Construction: Liquid level gauges are constructed from materials compatible with the liquid being measured, such as stainless steel, plastic, or glass. They may include components such as floats, chambers, valves, indicators, transmitters, and displays.

-

Installation: Liquid level gauges are installed on the tank or vessel according to the manufacturer's guidelines. Proper positioning, alignment, and calibration are essential for accurate and reliable measurements.

-

Applications: Liquid level gauges are used in industries such as oil and gas, chemical processing, pharmaceuticals, water treatment, food and beverage, power generation, and many others. They are employed in storage tanks, process vessels, reactors, boilers, and other equipment to monitor levels of liquids such as water, oil, chemicals, fuels, and beverages.

-

Maintenance: Regular inspection, cleaning, and calibration of liquid level gauges are necessary to ensure accurate readings and optimal performance. Any malfunctioning components should be promptly repaired or replaced to prevent operational issues or safety hazards.

Overall, liquid level gauges are indispensable instruments for monitoring and controlling liquid levels in industrial processes, contributing to efficient operations, regulatory compliance, and safety. The selection of the appropriate type of gauge depends on factors such as the type of liquid, operating conditions, accuracy requirements, and budget considerations.

-

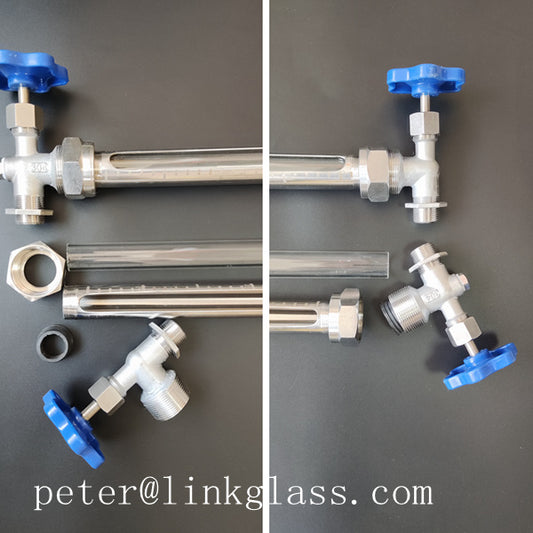

Stainless steel Cock valve glass tube liquid level gauge

Regular price $0.00 USDRegular priceUnit price / per -

Stainless steel Cock for liquid level gauge and indicator

Regular price $0.00 USDRegular priceUnit price / per -

Silica gel rubber gasket for cock liquid level gauge

Regular price From $2.50 USDRegular priceUnit price / per -

EPDM Ethylene Propylene Diene Monomer gasket for tube liquid level gauge

Regular price From $2.50 USDRegular priceUnit price / per -

PTFE polytetrafluoroethylene gasket for tube liquid level gauge

Regular price $6.00 USDRegular priceUnit price / per -

FKM gasket Viton Rubber Gasket fluoro rubber gasket for cock liquid level gauge

Regular price From $4.00 USDRegular priceUnit price / per -

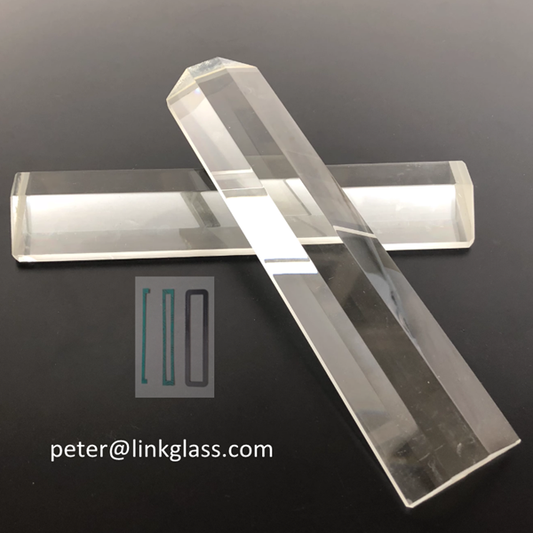

level gauge glass double-color water level gauge glass prism 216*50*22mm trapezoidal glass plate liquid level gauge high temperature resistant glass

Regular price From $18.40 USDRegular priceUnit price / per -

Air Compressor Oil Sight Glass, G 3/4" Male Thread Brass Oil Liquid Level Gauge Air Compressor Parts with O-ring

Regular price $0.00 USDRegular priceUnit price / per -

1/2'',3/4'' NPT Air compressor Oil Sight Glass, Bull Hex Head Brass Compresssor Oil Sight Glass, Heavy Duty Solid Brass Oil Sight Glass Liquid Level Gauge Oil Indicator Window For Air Compressor Gearbox Tank

Regular price $0.00 USDRegular priceUnit price / per -

Oil Liquid Level Gauge Sight Glass 1/2'' NPT Male Threaded Aluminum Alloy Air Compressor Fittings with O-ring

Regular price $0.00 USDRegular priceUnit price / per -

1/2'',3/4" NPT Air Compressor Oil Sight Glass, Male Thread Aluminum Alloy Oil Liquid Level Gauge Air Compressor Parts for Air Compressor Gearbox Tank

Regular price $0.00 USDRegular priceUnit price / per -

Male Hex Head 304 Stainless Steel Oil Sight Glass Sight Plug Liquid Level Gauge Oil Indicator Sight Window for Air Compressor Gearbox Fittings Hydraulic Tank

Regular price $0.00 USDRegular priceUnit price / per -

3/4 NPT Oil Sight Glass/Male Hex Head Compresssor/Oil Sight Glass Heavy Duty Solid/ Brass Oil Sight Glass Liquid Level Gauge Oil Indicator Window For Air Compressor Gearbox Tank

Regular price $0.00 USDRegular priceUnit price / per -

Oil Liquid Level Gauge Meter Hex Oil Level Gauge Transparent Display Good Sealing Accurate Measurement for Hydraulic System

Regular price $0.00 USDRegular priceUnit price / per